Slurry Force Silt Separators

The Slurry-Force Silt Separator Tanks are used as an efficient alternative to traditional gravity separating methods where discharge to sewer/waterways is required. Applications include on-site water management, wheel wash stations, CHPP drains and anywhere that suspended solids removal is required.

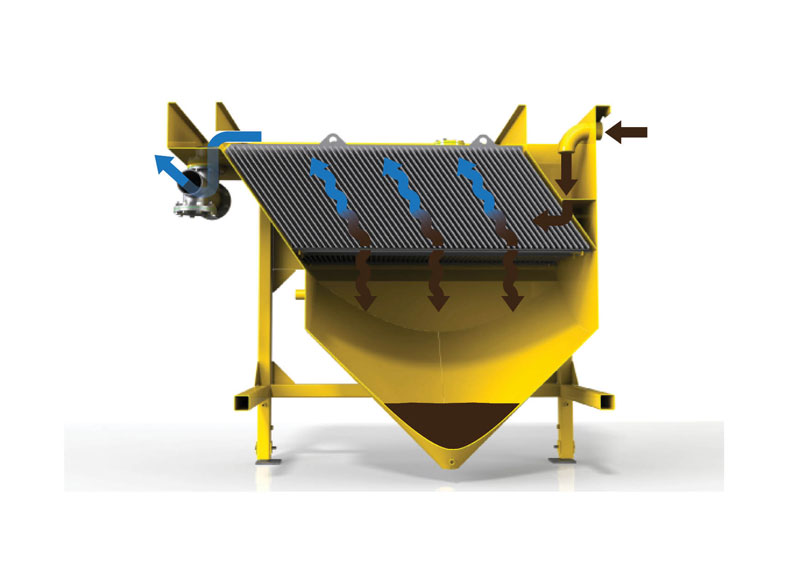

The Slurry-Force silt separator tank works by directing the flow of dirty water or slurry through a series of lamella plates within the tank allowing you to pump without discharging solids into sewer and waterways. These plates maximise effective settling area and minimise unit footprint.

All units are fitted with a 4” Bauer type couplings on the inlet, outlet and sludge drain point for ease of use with standard layflat hose.

Slurry-Force Silt Separator tanks can be configured as single units or in a series of multiple units to match required flows and increase settling times.

Units can also be coupled with polymer dosing systems to achieve optimal results.

Applications

- Civil Construction Sites

- Tailings Treatment

- Underground Mining

- Wheel Wash Systems

- Waterway Rehab Projects

Features

- Simple to transport, install & operate

- Height adjustable legs for discharge

- Removable Skid

- Fork Tyne Slots

- Air injection connection points

- Quick Connect Inlet & Outlet fittings

Options

- Air actuated discharge Valve

- Chemical treatment system for improved settling rates.