TRU-FLO PUMPMASTER PUMPS ID-FLEX CONTROL PANEL

- The codes or texts below may appear on your Tru-Flo PumpMaster screen.

- These codes appear for a reason – once you have diagnosed the issue, only then press Fault Reset.

- Once you have pressed Fault Reset, the hash and code will be removed. This will allow you to

- re-run the pump.

- Remember that all the codes are stored within the panel.

- Pressing the page, up or down button will cycle back to the home screen.

IMPORTANT: DO NOT HOLD DOWN THE BUTTONS UNLESS INSTRUCTED.

*EMERGENCY STOP

Actions: Reset the E Stop or the unit will not operate. Once reset, press Fault reset to remove the code and allow starting. (Check both E Stops if applicable).

*CD FLOW SWITCH

The pump has had no flow for 180 seconds after idle time.

TROUBLESHOOTING:

- Check suction strainer is not blocked or under mud.

- Ensure discharge isolation valve is open.

- Ensure discharge line is not blocked.

- Ensure the pump is not “Dead Heading” i.e. Discharge pressure beyond the pump’s capacity.

- Suctions lines maybe delaminated internally. This is collapsing internally and may not be visual externally. Delamination can occur in suction lines; this can result in limited or no flow.

- Ensure there is flow, even if it involves draining the line and removing the discharge line from pump.

Actions: Check above, unless visually other issues can be seen. Press fault reset to enable re-running of the pump.

*Wrn PUMP DISCHARGE PRESSURE

PumpMaster pump has had low discharge pressure.

*CD PUMP DISCHARGE PRESSURE

PumpMaster pump shut down due to low discharge pressure.

TROUBLE SHOOTING:

- Ensure the isolation valve is set correctly. This may close even during normal operation.

- Ensure the pressure gauge is operating and working on the “Best Pressure” range (chart located inside the control panel door).

- Ensure the water pump is not “Dead Heading” i.e. Discharge pressure beyond the jet pump’s capacity.

- Check the pressure reading on the pressure controller panel. This should read approximately zero (0) when pump is not operating.

- Ensure the pipeline has not burst, resulting in loss of pressure.

Actions: Press fault reset to enable running of pump.

*Wrn PUMP SUCTION PRESSURE

Pump has too greater suction lifts.

*CD PUMP SUCTION PRESSURE

Pump shut down, suction pressure to high. This means pump is vertically too far from the water source.

TROUBLESHOOTING:

- Check suction strainer is not blocked or under mud.

- Ensure the suction liner is not kinked or blocked

- Ensure the pumpset is as close to the water source as possible. The shorter the suction line the better. If the water is more than 3 metres vertically away from the pumpset, this may be too far. Move the pump closer to the water, even if it involves building another pad closer to the water.

- If vacuum gauge shows greater than -60kpa when pump is operating, the suction lift or condition is too high for the pump.

- Suction lines may be delaminated internally. This is collapsing internally and may not be visual externally. Delamination can occur in suction lines this can result in limited or no flow.

Actions: Check above, move pump closer to water source. Press fault reset to enable re-running of pump.

*Wrn FUEL LEVEL

Fuel level is below 10%. Fuel tank needs refilling.

*CD FUEL LEVEL

Fuel level is below 5%. Pump will stop operating. Refuel and reset, bleeding should not be needed. The engine will shut down in protection mode to protect the pump, motor and other critical components.

Note: CD pump pressure and CD flow switch may also be visible on the screen. This is due to the control panel shutting the engine down.

Actions: Check above, fill unit with fuel. Press fault reset to enable re-running of pump.

*Wrn PUMP TEMPERATURE

Temperature sensor has sensed temperatures of 40°.

*CD PUMP TEMPERATURE

Pump shut down due to high pump casing temperature. Temperature will have reached at least 50°.

TROUBLESHOOTING:

- Ensue isolation valve is open.

- Ensure discharge pressure is not exceeding the maximum pressure (chart located inside the control panel door). If the pressure is greater than the maximum pressure, the pump may be “Dead Heading” or not pumping.

- The discharge pressure may be beyond the pump’s capacity. This will cause the friction within the pump the cause the temperature to rise.

- Ensure the pump is priming. If the pump is not primed or priming, the fluid in the pump casing may be getting hot. Eliminate this by removing the rubber line from the top of the suction chamber, hold your hand over the end of the rubber line to ensure the Vac Pump is working. This must be performed when engine is running.

Actions: Check the above, press fault reset to enable re-running of pump. Replace the temperature sender located on the bottom of the pump.

*Wrn COOLANT TEMPERATURE

Engine cool system is overheating and is above maximum temperature.

*CD COOLANT TEMPERATURE

Engine shut down. Temperature is above maximum.

TROUBLESHOOTING:

- Check coolant level and top up if necessary

- Check the radiator is not blocked with dust, silt, grass, or plastic bags.

- Ensure the fan is operating correctly, including the correct tightness of the belt to manufactures specifications.

*Wrn OIL PRESSURE

Oil pressure is too low.

*CD OIL PRESSURE

Oil pressure is below one (1) bar. Engine will shut down.

Actions: Check oil level.

*CD UNDERSPEED

Control panel recognises that engine speed under has gone 15% under the idle speed.

*CD START FAIL

Engine has tried to start 3 times and has failed.

TROUBLESHOOTING:

- Generally, fuel issues, out of fuel or blocked fuel filter.

- If you have Red and Yellow Isolators, ensure the Yellow Isolator is on.

- Check the ECM Fault Codes for active faults. This means the engine has shut down for an unexplained reason, NOT A PUMP ISSUE. Suggest the revs may have been too low, engine was over loaded, blocked fuel filter.

- Get technician to assess the situation. The engine manufacturer may also be required to diagnose the issue.

Actions: Change fuel filter and purge fuel lines. Turn on the yellow isolator.

The codes above may appear on your Pump Master screen. There are many others also.

If an ECU Warning or Error occurs, do not start the engine, call Tru-Flo or your engine service team.

These are 3 codes that appear on the bottom line of the control panel screen, when an engine fault occurs. Codes OC and FMI numbers are important. Record or write down the code to relate this to your Tru-Flo representative or engine support team.

Before pressing Fault Reset, always diagnose the issue. Your Tru-Flo representative may be able to assist over the phone, so don’t hesitate to contact.

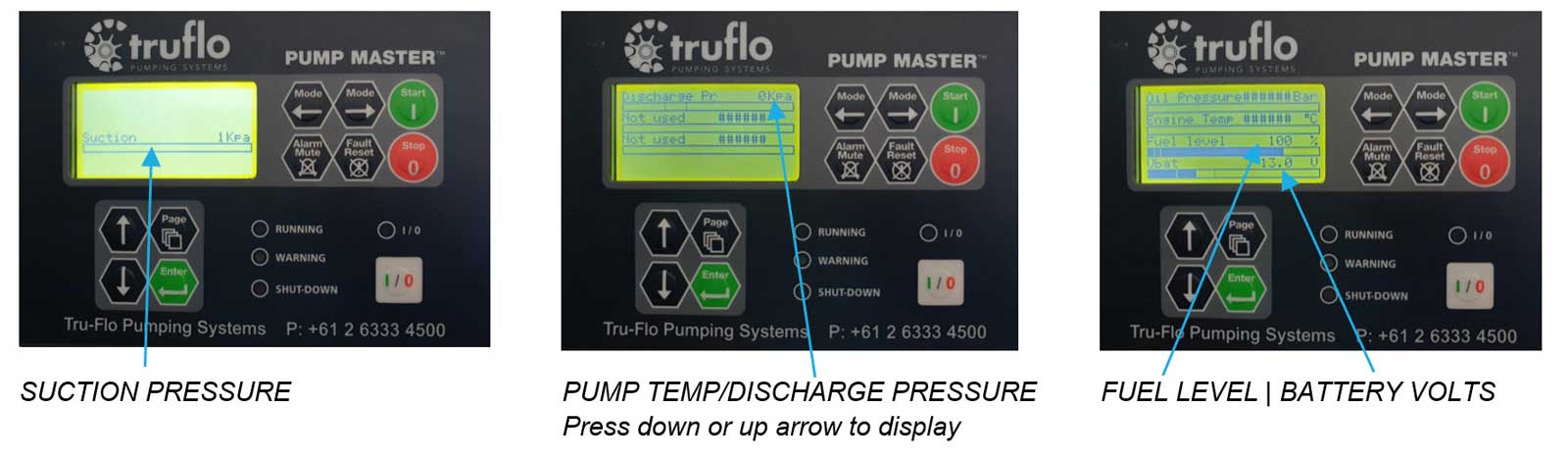

Whenever you see ##### on pressure, suction, pump, temperature, fuel level, oil pressure and engine temperature this means sensor is faulty or wiring has an open circuit.

REMEMBER

- All faults are logged with the time and date.

- If the same fault is logged more than once, something is wrong.

- It could be something very simple that you can diagnose yourself the above trouble shooting

- is only a guide.

- If in doubt ask, as serious damage may occur if pumps are used outside their operating range.

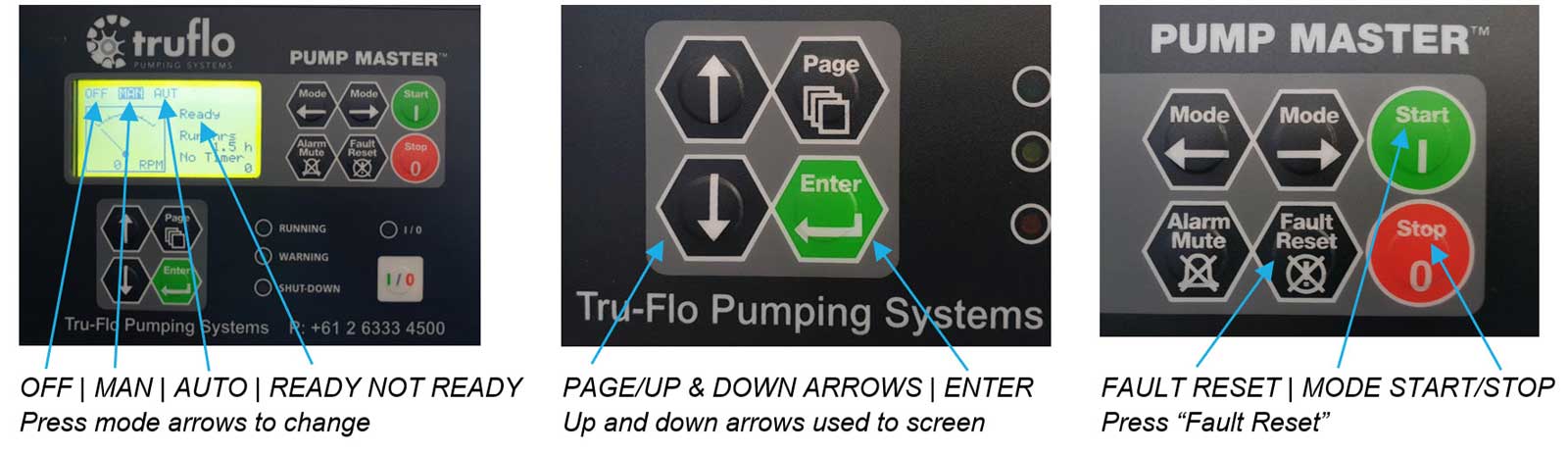

CONTROL PANEL DISPLAY & BUTTONS